Case Study Industry 4.0 Controller

Learn how PC 11X3C1 automated data collection and reporting, facilitating intelligent load balancing and improving overall Package AC health and reliability.

Impact Summary:

✅ Upgraded the package AC with Industry 4.0 technology and a PC 11X3C1 controller, enhancing the equipment's lifespan.

✅ 21% efficiency increase in mission critical Package AC within the first year.

The Challenge:

Oil refining process is highly dependent on Variable Frequency Drives (VFD). The process relies heavily on precise temperature management to control the refining process. This is an industry where any downtime of Package AC effects the refining process. Thus, process continuity and efficiency is mission critical and also one of the high energy consuming equipment.

An Indian refining giant was plagued by Package AC-related issues where the operational team was facing challenges in keeping up with Package AC maintenance. The various aspects of the challenge included faulty OEM electronic controller which eventually failed after commercialization of the project, unavailability of spares, high maintenance costs, unavailability of benchmarks and heavy reliance on manual data collection. As a result, Package AC were broken down or operating sub-optimally and fouling frequently, effecting the production process. All of this combined was driving up operational costs and lowering profitability of the plants.

The company was ready for a change and was on the lookout for a solution that would help them with revive the failed units, smooth and optimized Package AC operations for the foreseeable future. It was also harming their internal goals as a sustainable business. It had to be resolved fast and effectively.

The refining giant reached out to Ramhe Technologies with an interest to test out the flagship industry 4.0 platform PC 11X3C1. Using proprietary algorithms that handle data analysis and monitoring at asset level providing the psychrometry analytics, PC 11X3C1 was the ideal answer to the Package AC efficiency situation. It gives the operations team a real-time dashboard with timely updates and instant alerts the moment something needs their attention

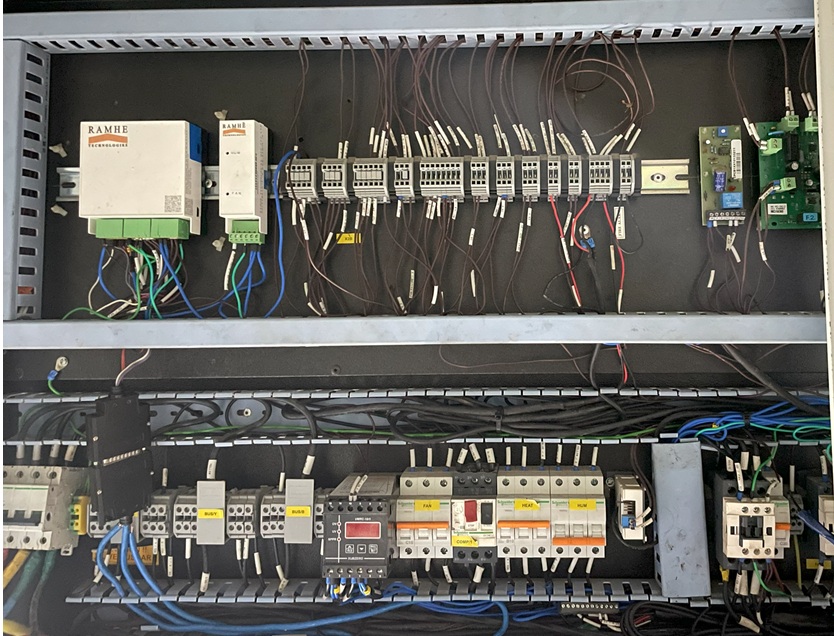

As part of the pilot, the company tasked the Ramhe Technologies team with deploying PC 11X3C1 for the package AC installed at one VFD room

Package AC was fitted with sensors for PC 11X3C1 controller, and the data was live on touch screen HMI dashboard, giving engineers immediate alerts on any deviations or fouling of condensers or evaporators at the Package AC. This created an on-demand maintenance model, which was more cost and time-effective than the previous reactive method based on manual data collection.

About 12 sensors were installed as part of the overall project and they provided a data break-up of each asset into sub-assets, providing accurate and granular monitoring and data analytics. The AI algorithm optimized the unit performance by operating in free cooling mode. The client team began not only to operate the broken Package AC but also gain insights into the performance of the system.

PC 11X3C1 also provided trend analysis comparing before and after figures, giving exact numbers for potential savings for the company.

The Outcomes:

As a direct result of the strategic deployment of PC 11X3C1, the client team was able to bring-up and track Package AC operational health and power consumption with greater speed and accuracy. Here is how we helped the client team get the best out of their Package AC.

✅Using the state of art industry 4.0, PC 11X3C1, Ramhe team was able to upgrade the faulty OEM controller and operate the unit.

✅Using the state of art industry 4.0, PC 11X3C1 analytics, the Ramhe team was able to increase efficiency of a Package AC unit by 21%.

✅MIS reports and monthly usage reports were automated, analysing and comparing Package AC efficiency based on approach temperature and other factors.

✅Real-time monitoring makes the root cause of inefficiencies clear and reduces increased energy consumption due to fouling.

✅Intelligent load balancing cuts downtime and increases the overall health of each Package AC by efficiently managing load distribution across available assets.

This is how the Ramhe team leveraged PC 11X3C1 to resolve operational and critical maintenance issue, optimise operational efficiency, automate data collection and reporting and accelerate the Net-Zero journey of the client.

Convinced by the performance during the pilot, the client then decided to expand the partnership with Ramhe Technologies, which is ongoing till date.

If you want to know more about how PC 11X3C1 and the Ramhe team of experts can enhance the operational efficiency, transform maintenance, and increase overall profitability for your industrial units, contact us today to book a personalised demo.

-We also work on other OEM Systems like: